How Ultra Pure Gas Delivery Supports Industrial Growth

Monday 24th of February 2025An Ultra High Purity Gas Delivery System is an essential element in industries where precision and contamination-free procedures are crucial. These systems make sure the safe and effective transportation of gases with the highest purity degrees, playing a significant role in semiconductor manufacturing, pharmaceutical manufacturing, and lab. Any pollutant in gas circulation can lead to defective items and endangered outcomes, making the proper layout and execution of these systems essential for keeping high quality and performance.

Designing an Ultra High Purity Gas Delivery System in Market

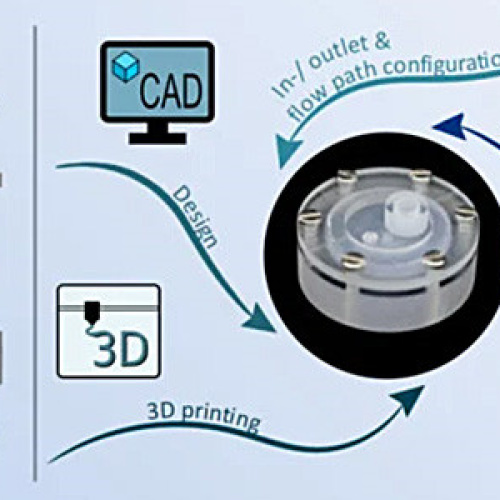

The style of an Ultra High Purity Gas Delivery System needs cautious planning and advanced design strategies to ensure the purity of gases continues to be undamaged. The system needs to consist of premium products such as electro-polished stainless-steel and specialized filtration systems to avoid contamination. Watertight links, automated monitoring, and exact stress control systems are likewise necessary for keeping constant gas high quality. These systems are commonly made use of in microelectronics, aerospace, and biotechnology markets, where also the tiniest contamination can impact overall performance and reliability.

Manufacturing Ultra High Purity (UHP) Gas and Chemical Shipment Systems

The procedure of Manufacturing Ultra High Purity (UHP) Gas and Chemical Distribution Solution involves strict adherence to sector criteria and the use of cutting-edge technology. UHP gas delivery systems need to be developed to transport specialized gases and chemicals without presenting impurities. This requires the use of innovative welding strategies, gas purification systems, and real-time surveillance services. Industries such as semiconductor construction and fiber optics production depend on these systems to keep the highest levels of purity and precision throughout their manufacturing procedures.

The Importance of Ultra High Purity Regulatory Authorities and Diaphragm Shutoffs

Trick elements of any kind of ultra high pureness gas system include Ultra High Pureness Regulatory Authorities and Ultra High Purity Diaphragm Valves, both of which make sure accurate gas circulation control and contamination avoidance. These regulatory authorities are created to maintain stable pressure levels while protecting against fragment build-up, while diaphragm valves supply precision circulation control with marginal inner dead room. Made from state-of-the-art, corrosion-resistant products, these components play an essential function in sectors needing absolute purity and integrity in gas distribution.

High Pureness Regulators for Specialty, Flammable, and Industrial Gas Streams

Industries taking care of specialty, combustible, and industrial gases require High Purity Regulatory authorities for Usage with Specialty, Flammable, and Industrial Gas Moves to ensure safety and security and effectiveness. These regulatory authorities are particularly made to take care of numerous gas kinds while preserving purity and avoiding leaks. Whether utilized in chemical processing, pharmaceutical applications, or semiconductor manufacturing, high-purity regulatory authorities aid keep operational stability and safeguard delicate devices from contamination-related failings.

Conclusion

An Ultra High Purity Gas Delivery System is necessary for industries that rely on contamination-free gas transport. From system design to the combination of high-purity regulatory authorities and diaphragm shutoffs, these systems offer dependability, precision, and security popular industrial environments. As technology developments, the requirement for ultra high pureness gas systems will continue to expand, supporting the advancement of sophisticated industries and ensuring remarkable product high quality.